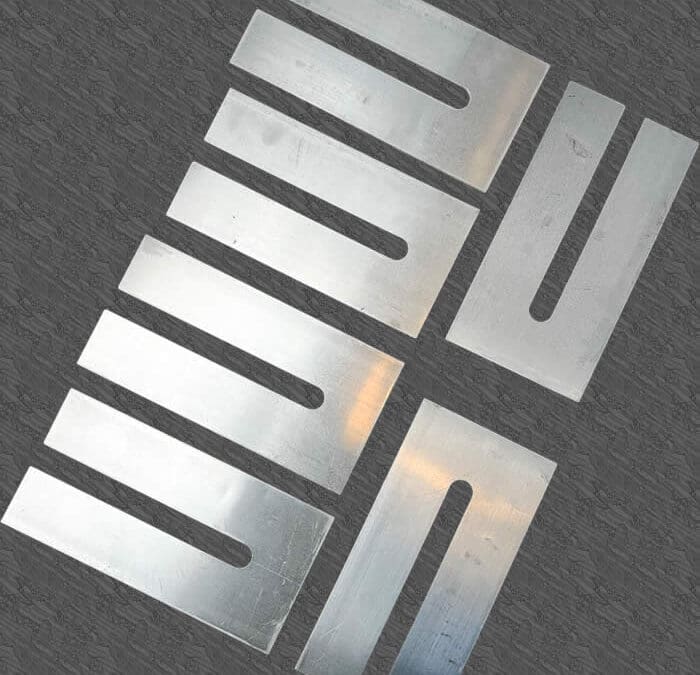

Manufacturers today face increasing demands for accuracy, speed, and efficiency. In gasket production, the need for consistent, high-quality components is essential. From sealing critical machinery to meeting industry compliance standards, a gasket’s performance depends on its precise fit. Laser cutting technology has transformed how custom gaskets are made, ensuring tight tolerances and consistent results every time.

At Stephens Gaskets, we have invested in advanced laser cutting technology to deliver exceptional quality in gasket production. Our team combines decades of manufacturing experience with state-of-the-art machinery to meet even the most demanding requirements.

From one-off prototypes to large production runs, we work closely with clients to ensure every gasket is cut to perfection. Our precision cutting services are trusted across industries for reliability, speed, and accuracy.

The Importance of Precision in Gasket Manufacturing

Gaskets are used in a wide range of industries, including automotive, aerospace, oil and gas, marine, and manufacturing. Their role is to create a secure seal between surfaces, preventing leaks and withstanding extreme conditions.

A poorly cut gasket can cause:

- Leakage, leading to machinery failure

- Increased maintenance costs

- Downtime in production

- Safety hazards

Tight tolerances are critical. Even a slight variation can compromise the seal. This is where precision cutting services excel, offering accuracy down to fractions of a millimetre.

How Laser Cutting Works in Gasket Production

Laser cutting uses a concentrated beam of light to cut through materials with pinpoint accuracy. In custom gasket manufacturing, the process often involves:

- Creating a digital CAD design of the gasket

- Uploading the design to a CNC laser cutting machine

- Using the laser to follow the design path exactly

The result is a clean, burr-free edge with no need for secondary finishing. This method works across metals, rubbers, plastics, and composites, making it ideal for the diverse materials used in gasket production.

Advantages of Laser Cutting Technology for Gaskets

1. Accuracy and Tight Tolerances

Laser cutting achieves exceptional accuracy. This ensures each gasket matches design specifications exactly, even on repeat orders.

2. Complex Designs Without Tool Changes

Unlike traditional methods, lasers can cut intricate profiles without switching tools, reducing downtime and increasing production speed.

3. Minimal Waste

By nesting designs closely together on a sheet, laser cutting technology maximises material usage, reducing costs and environmental impact.

4. Fast Turnaround

Digital-to-production workflows make it possible to produce parts quickly, meeting urgent deadlines without compromising quality.

5. Versatility in Materials

From stainless steel to rubber and high-temperature composites, lasers handle a wide range of gasket materials with consistent results.

Why CNC Laser Cutting is Ideal for Custom Gasket Manufacturing

CNC laser cutting combines automation with precision. Once the design is programmed, the machine executes the cut identically every time. This consistency is vital in industries where parts must meet strict quality control standards.

For custom gasket manufacturing, CNC lasers offer:

- Quick setup for new designs

- Easy adjustments for design updates

- High repeatability for large production runs

- The ability to switch between materials without extensive retooling

The Role of Laser Cutting in Reducing Production Waste

In manufacturing, waste reduction is a key factor in controlling costs and meeting sustainability goals. Laser cutting allows gaskets to be nested tightly on a material sheet, significantly reducing offcuts.

The process is also non-contact, meaning there’s no tool wear. This eliminates the need for regular tool replacements, reducing both costs and production interruptions.

Meeting Industry Standards with Laser Cutting Technology

Many industries operate under strict quality and safety standards. Precision laser cutting for gaskets ensures that every component meets these standards by delivering consistent, repeatable results.

For example:

- In automotive applications, exact gasket dimensions help prevent engine oil leaks.

- In aerospace, precision ensures sealing in high-pressure environments.

- In industrial machinery, gaskets cut to tight tolerances reduce wear and tear on components.

Comparing Laser Cutting to Other Methods

Laser Cutting vs Die Cutting

Laser Cutting: No physical contact with the material, ideal for intricate designs, quick setup for small runs.

Die Cutting: Requires custom tooling, more suitable for very high-volume, low-variation production.

Laser Cutting vs Waterjet Cutting

Laser Cutting: Faster for thin to medium materials, offers a cleaner edge.

Waterjet Cutting: Better for extremely thick materials but slower and less energy-efficient.

The Future of Precision Laser Cutting for Gaskets

As industries demand higher precision and shorter lead times, laser cutting technology continues to advance. Integration with AI-driven design tools and automation systems will make custom gasket manufacturing even faster and more accurate.

We are seeing growing use of:

- Advanced nesting software to minimise waste

- Automated quality inspection systems

- Integration with supply chain management for real-time order tracking

FAQs

What materials can be laser cut for gaskets?

Laser cutting works on metals, rubbers, plastics, composites, and high-temperature materials.

Is laser cutting cost-effective for small production runs?

Yes, because there’s no tooling cost, making it ideal for prototypes and low volumes.

How accurate is CNC laser cutting?

Accuracy can be within a fraction of a millimetre, ensuring perfect fits every time.

Can laser cutting handle complex shapes?

Absolutely. Lasers excel at intricate profiles without the need for multiple tools.

Conclusion

Precision laser cutting for gaskets has redefined how manufacturers meet quality, speed, and cost targets. Its ability to deliver exact shapes, tight tolerances, and consistent results makes it the preferred choice for custom gasket manufacturing. With advances in laser cutting technology, businesses can produce gaskets that meet the highest industry standards while minimising waste and maximising efficiency.

If you need precision cutting services that combine speed, accuracy, and reliability, Stephens Gaskets offers expert CNC laser cutting for projects of any size.

Contact Stephens Gaskets

Phone: +44 (0)121 544 5808

Email: sales@stephensgaskets.co.uk