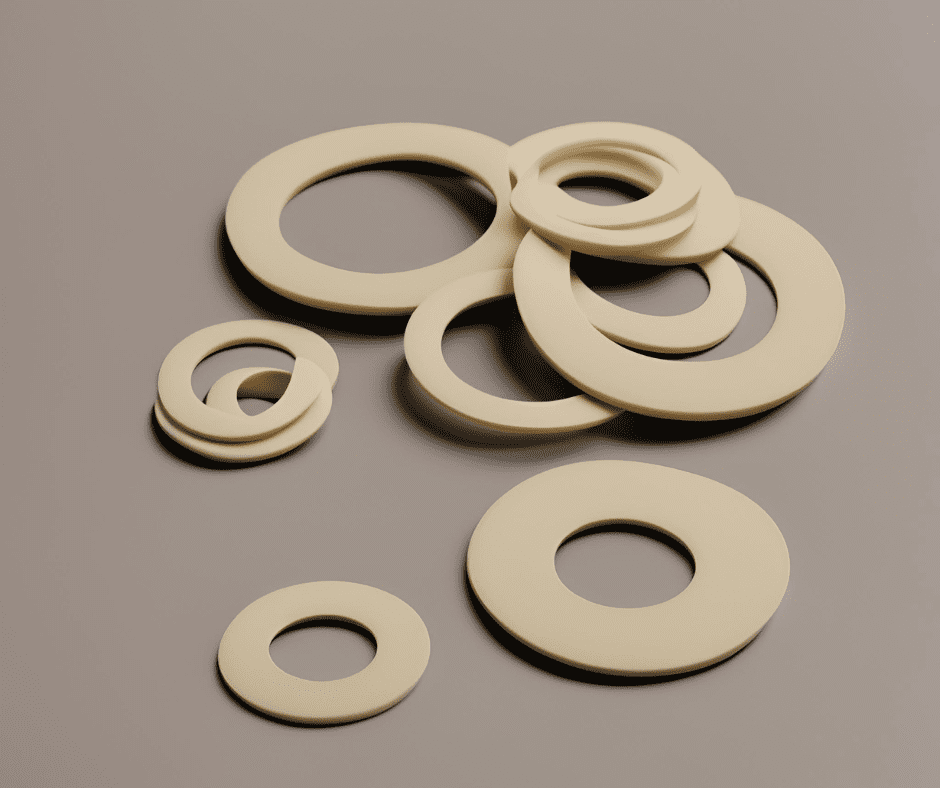

Latex Washers

Custom Gaskets for Every Application

Stephens Gaskets is Your Reliable Supplier for Latex Washers

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Global Leaders in Shim Solutions

As a trusted provider of shim solutions, we serve OEMs and businesses globally.

At Stephens Gaskets, we are a proud supplier of Latex Washers that can be custom made to meet the needs of our customers. Moreover, our experienced team is equipped with the latest technology and machinery to manufacture high-quality Latex Washers that are built to last.

If you’re seeking high-quality Latex Washers with a quick turnaround, look no further.

Our reputation as the best in the business is well-deserved. With over 70 years of experience delivering top-notch products that meet both your budget and timeline. Our commitment to quality and efficiency is unwavering.

What are Latex Washers?

Latex washers are circular sealing components made from natural or synthetic latex rubber. They are designed to fit between two surfaces to prevent leakage, absorb vibrations, and distribute pressure evenly. Here are some key characteristics and applications of latex washers:

Key Characteristics of Latex Washers:

Elasticity: These washers are highly flexible and can compress and return to their original shape, providing excellent sealing performance.

Durability: They offer good resistance to wear and tear, making them suitable for various applications.

Chemical Resistance: These washers are resistant to many chemicals, which enhances their longevity in harsh environments.

Temperature Tolerance: They can withstand a range of temperatures, although they are generally more suited to lower temperature applications compared to some synthetic alternatives.

Softness: The softness of these washers allows for a tight seal even with uneven surfaces.

These washers are valued for their flexibility, durability, and ability to create tight seals in a variety of applications.

What are the benefits of Latex Washers?

Latex washers offer several benefits that make them a popular choice for various sealing and cushioning applications. Here are some key advantages:

High Elasticity

Latex washers are highly elastic, allowing them to compress and return to their original shape. This property ensures a tight seal, even when there are slight imperfections or irregularities in the surfaces they are sealing.

Excellent Sealing Capability

Due to their flexibility and ability to conform to surfaces, latex washers provide an effective seal against leaks in plumbing, automotive, and industrial applications.

Durability

Latex washers are resistant to wear and tear, providing long-lasting performance. They can endure repeated compression and decompression cycles without losing their sealing properties.

Chemical Resistance

These washers are resistant to many chemicals, making them suitable for use in environments where they may be exposed to various fluids and gases.

Temperature Tolerance

They can operate effectively within a wide temperature range, although they are particularly well-suited to low and moderate temperatures.

Vibration Dampening

The softness and flexibility of latex washers allow them to absorb and dampen vibrations. This makes them useful in applications where reducing noise and vibration is important, such as in automotive and industrial machinery.

Cost Effective

Latex washers are relatively inexpensive compared to other materials, providing a cost-effective solution for sealing and cushioning needs.

Biocompatability

Natural latex washers are biocompatible, making them suitable for use in medical devices and equipment where contact with human tissue or fluids is necessary.

Eco-friendly

Natural latex is a renewable resource, making latex washers an environmentally friendly choice compared to synthetic alternatives.

What are the applications of Latex Washers?

Latex washers are versatile components used in a variety of applications across different industries. These applications highlight the versatility and importance of latex washers in providing reliable sealing, cushioning, and vibration dampening across various industries and products. Here are some common applications:

Plumbing

-

- Faucets and Valves: Latex washers provide a tight seal to prevent water leaks in faucets, valves, and other plumbing fixtures.

- Pipe Connections: Used in pipe joints to ensure leak-proof connections.

Medical Devices

- Equipment Seals: Employed in medical equipment where a reliable, biocompatible seal is required.

- Disposable Instruments: Used in various disposable medical instruments and devices.

Automotive

- Vibration Dampening: Latex washers help reduce noise and vibration in automotive components.

- Fluid Seals: Utilised in the sealing of automotive fluids such as oil, coolant, and brake fluid.

Industrial Machinery

- Cushioning and Isolation: Used to cushion and isolate vibrations in industrial machinery, enhancing performance and longevity.

- Fluid Containment: Ensures that hydraulic and pneumatic systems remain leak-free.

Garden Hoses

- Sealing: Used in hose connections to prevent water leakage.

Aerospace

- Sealing: Utilised in various aerospace applications where lightweight and effective sealing is crucial.

- Vibration Control: Helps in reducing vibrations in aircraft components.

HVAC Systems

- Seals and Gaskets: Latex washers are used in heating, ventilation, and air conditioning systems to prevent leaks and ensure efficient operation.

Laboratory Equipment

- Sealing and Cushioning: Provides effective seals and cushioning in various laboratory instruments and apparatus.

Specialized Applications

- Sporting Goods: Found in equipment such as bicycles and exercise machines to dampen vibrations and provide cushioning.

- Toys and Games: Used in the assembly of toys to ensure safety and durability.

- Agricultural Equipment: Employed in irrigation systems and machinery to prevent leaks and reduce vibrations.

Looking for a Latex Washers Supplier?

Stephens Gaskets is a leading supplier of high-quality Latex Washers. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Latex Washers and how we can help you with your next project.

Industry-Specific Materials for Latex Washers

In the manufacturing of latex washers, various industry-specific materials are used to meet the diverse requirements of different applications. Here are the primary materials commonly utilised:

Materials Used in Manufacturing Latex Washers:

- Natural Latex Rubber:

- Source: Derived from the sap of rubber trees (Hevea brasiliensis).

- Properties: High elasticity, excellent sealing capability, good resistance to water and many chemicals, biodegradable, and eco-friendly.

- Applications: Plumbing, medical devices, food and beverage industry, and consumer goods.

- Synthetic Latex Rubber:

- Source: Produced from petrochemical sources, synthetic latex includes materials like styrene-butadiene rubber (SBR), nitrile rubber (NBR), and others.

- Properties: Enhanced resistance to oils, fuels, and chemicals; better temperature resistance compared to natural latex; improved durability.

- Applications: Automotive, aerospace, industrial machinery, and electrical applications.

Specific Types of Synthetic Latex Rubber:

- Styrene-Butadiene Rubber (SBR):

- Properties: Good abrasion resistance, ageing stability, and cost-effectiveness.

- Applications: Automotive seals, industrial gaskets, and general-purpose washers.

- Nitrile Butadiene Rubber (NBR):

- Properties: Excellent resistance to oils, fuels, and other chemicals; good temperature range performance.

- Applications: Automotive fuel systems, industrial hydraulic systems, and applications requiring resistance to oil and chemicals.

- Ethylene Propylene Diene Monomer (EPDM):

- Properties: Outstanding resistance to weathering, ozone, and UV exposure; excellent water and steam resistance.

- Applications: HVAC systems, outdoor equipment, and applications exposed to weather elements.

- Chloroprene Rubber (Neoprene):

- Properties: Good chemical stability, flexibility over a wide temperature range, and moderate resistance to oils and chemicals.

- Applications: Marine applications, refrigeration seals, and general-purpose industrial washers.

- Silicone Rubber:

- Properties: Excellent thermal stability, resistance to extreme temperatures, flexibility, and inertness.

- Applications: Medical devices, food processing equipment, and applications requiring high-temperature resistance.

- Fluoroelastomer (Viton):

- Properties: Exceptional resistance to high temperatures, chemicals, and aggressive fluids.

- Applications: Aerospace, automotive, and chemical processing industries where extreme conditions are present.

Choosing the Right Material:

The choice of material for latex washers depends on the specific requirements of the application, including factors like:

- Chemical Compatibility: Resistance to chemicals, oils, and fuels.

- Temperature Range: Ability to withstand extreme temperatures.

- Mechanical Properties: Elasticity, durability, and abrasion resistance.

- Environmental Exposure: Resistance to weathering, UV light, and ozone.

- Biocompatibility: Safety for use in medical and food-related applications.

Manufacturers select materials based on these criteria to ensure that the latex washers perform effectively in their intended applications, providing reliable sealing, cushioning, and vibration dampening.

Issues common with Latex Washers

Allergic Reactions: Natural latex contains proteins that can cause allergic reactions in some individuals, leading to skin irritation, rashes, or more severe reactions. This limits the use of natural latex washers in medical devices and applications where contact with human skin is frequent.

Limited Temperature Range: Latex washers, especially those made from natural latex, have a relatively narrow temperature range. They can degrade or lose their elasticity at higher temperatures, making them unsuitable for high-temperature applications such as certain automotive and industrial uses.

Chemical Sensitivity: Although latex washers have good resistance to many chemicals, they are vulnerable to degradation by oils, solvents, and some chemicals. This reduces their effectiveness in applications involving exposure to harsh chemicals or oils, necessitating alternative materials like nitrile or fluorocarbon.

UV and Ozone Degradation: Natural latex is susceptible to degradation from prolonged exposure to ultraviolet (UV) light and ozone, limiting the lifespan and effectiveness of latex washers in outdoor applications unless additional UV stabilisers are added.

Mechanical Wear: Latex washers can wear out more quickly under mechanical stress, especially in applications involving high friction or constant movement. This shortens the maintenance intervals and increases the frequency of replacements in dynamic environments.

Cost Variability: The cost of natural latex can fluctuate due to changes in the supply of raw materials, influenced by environmental and economic factors. This can affect the pricing stability of latex washers, making budgeting and cost management more challenging for manufacturers and consumers.

Manufacturing Constraints: Producing latex washers with precise dimensions and consistent quality can be challenging, particularly for custom sizes and shapes. This may result in increased production costs and lead times, affecting the overall efficiency of the manufacturing process.

Biodegradability Concerns: While natural latex is biodegradable, synthetic latex materials may not decompose easily and could contribute to environmental pollution. This raises environmental concerns, particularly for industries and consumers prioritising eco-friendly solutions.

Compatibility Issues: Latex washers may not be compatible with certain substrates or surfaces, leading to poor adhesion or sealing performance. This requires careful selection and testing to ensure proper function in specific applications.

Addressing these issues involves selecting the appropriate material for the specific application, considering alternative materials when necessary, and implementing design and manufacturing practices that mitigate these issues.

Need Guidance on Latex Washers?

Stephens Gaskets is a leading supplier of high-quality Latex Washers. With over 70 years of experience in the industry, we have a deep understanding of the needs of our customers. We commit ourselves to providing top-notch products and services for companies nation wide.

Get in touch with us today to learn more about our Latex Washers and how we can help you with your next project.