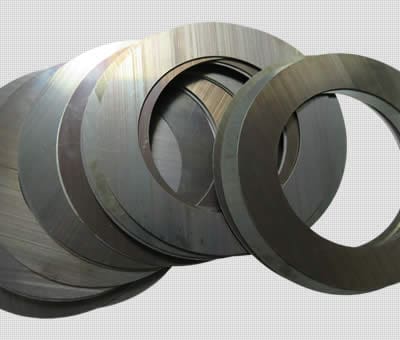

Heat Treated Shims

Heat Treated Shims for Demanding Engineering Applications

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Why Choose Stephens Gaskets?

As an established heat treated shims supplier,

We provide:

- Precision-ground shims in hardened steels and alloys.

- Custom designs to suit complex assemblies.

- Heat treatment options including hardening, tempering, and annealing.

- Corrosion-resistant or coated variants.

- Full traceability and technical support.

What Are Heat Treated Shims?

Heat Treated Shims are metal components that undergo heat treatment to enhance their mechanical properties. This process improves hardness, strength, wear resistance, and dimensional stability – essential in high-load or high-temperature environments.

Heat Treatment Methods:

- Hardening: Increases surface and core strength.

- Tempering: Reduces brittleness.

- Annealing: Improves ductility and machinability.

- Normalising: Enhances structural uniformity.

Benefits of Heat Treated Shims

Choosing heat treated shims from Stephens Gaskets brings:

1. Superior Wear Resistance

Ideal for abrasive or high-friction environments.

2. Enhanced Load Capacity

Handles compressive and shear loads without deformation.

3. Dimensional Accuracy

Maintains thickness and form under thermal and mechanical stress.

4. Thermal Stability

Performs reliably in engines, turbines, and heated systems.

5. Impact & Fatigue Resistance

Suitable for rotating machinery and high-cycle operations.

6. Longer Service Life

Reduces need for replacement, minimising downtime.

7. Batch Consistency

Uniform properties ensure predictable performance.

8. Corrosion Protection

Available in stainless steel or with specialist coatings.

Where Are Heat Treated Shims Used?

Our shims are used in environments that demand reliable alignment and resilience under pressure:

- Engine and turbine assembly.

- Airframe component spacing.

- Landing gear alignment.

- Transmission and gearbox setup.

- Valve train spacing.

- Suspension alignment.

- Shaft and bearing positioning.

- Gearbox mounting.

- Hydraulic system spacing.

- Machine calibration.

- Die and mould alignment.

- Jig and fixture setups.

- Steam and gas turbines.

- Pump and motor alignment.

- Systems subject to thermal expansion.

- Valve and compressor mounts.

- Offshore engine alignment.

- Pipeline support systems.

Material Options for Heat Treated Shims

We offer high strength shims in the following materials:

| Material | Properties | Ideal Use Cases |

|---|---|---|

| Carbon Steel | High strength, heat-treatable | Heavy machinery, die setups |

| Stainless Steel | Corrosion-resistant, durable | Marine, chemical, aerospace |

| Tool Steel | Extremely hard and wear-resistant | Punch and die alignment |

| Alloy Steel | Balanced strength and ductility | Automotive and industrial components |

| Spring Steel | High yield strength | Dynamic systems under vibration |

| Titanium | Lightweight, corrosion-resistant | Aerospace, defence |

Addressing Common Problems

High Cost?

We offer efficient production and bulk discounts to reduce unit price.

Risk of Brittleness?

Proper tempering ensures toughness and prevents cracking.

Warping During Treatment?

Post-heat-treatment grinding restores flatness and tolerance.

Long Lead Times?

We keep stock of common sizes and offer rapid custom fabrication.

Hard to Modify On Site?

We deliver finished parts to exact spec, so no field adjustment is needed.

Specialised Tooling Needed?

We handle all surface finishing, hardness testing, and inspection in-house.

About Stephens Gaskets

Stephens Gaskets is an experienced UK Heat Treated Shims Company supplying OEMs, contractors, and precision engineers since 1947. Our in-house production, expert team, and rigorous QA ensure that every shim meets the demands of today’s toughest applications.

From aerospace engines to offshore rigs, we manufacture to perform.

FAQs

Do you offer custom shim shapes?

Can I get technical data sheets or certifications?

How accurate are your tolerances?

Do you provide sample packs?

What's the turnaround time?

Work With a Trusted Heat Treated Shims Supplier

Our team combines metallurgical expertise, precision tooling, and responsive service to get the job done.

Send us your drawing OR spec today – we’ll take care of the rest.