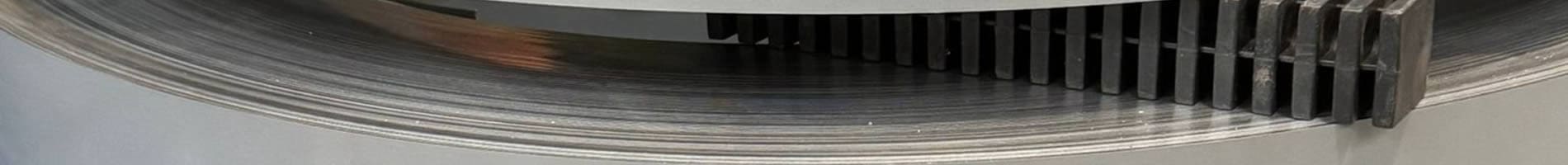

Bespoke Electrical Laminations

Bespoke Electrical Laminations

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Why Choose Bespoke Electrical Laminations?

Standard laminations often lead to wasted space, excess noise, and reduced efficiency.

Bespoke laminations from Stephens Gaskets solve these problems:

- Reduced Core Losses: precision-stamped or laser cut to minimise eddy currents.

- Custom Design: non-standard shapes and sizes for unique requirements.

- Material Optimisation: from silicon steels to amorphous metals, chosen to match your application.

- Scalable Production: laser cut for prototypes, die-stamped for volume runs.

- Compliance & Quality: meeting UK, EU, and global standards for electrical cores.

Industries We Serve

Bespoke electrical laminations are essential wherever performance, efficiency, and reliability are critical:

Materials for Bespoke Laminations

We supply laminations in a variety of high-grade electrical steels and alloys, including:

1. Non-Oriented Electrical Steel (NOES)

Best for motors and rotating machinery.

2. Grain-Oriented Electrical Steel (GOES)

Tailored for transformers and power distribution.

3. Amorphous Metals

ultra-low losses for energy-efficient applications.

4. Nanocrystalline Alloys

Lightweight, high-performance solutions for EVs and aerospace.

Pain Points We Solve

- Overheating motors: reduced energy losses with optimised laminations.

- Space & weight limitations: bespoke designs reduce footprint and weight.

- Noise & vibration: low-magnetostriction steels cut noise significantly.

- Inefficient energy use: advanced alloys improve energy efficiency and lower lifetime costs.