Support Washers

High-Performance Support Washers for Soft Material Fastening

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

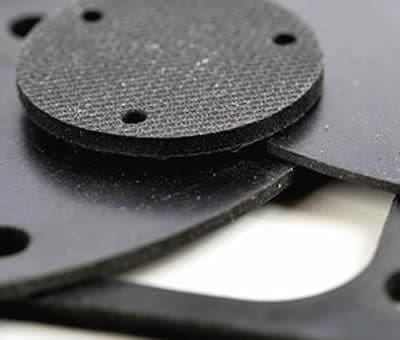

If your application requires securing rubber gaskets, plastic components, or other deformable materials, our support washers offer a proven solution. We deliver exceptional quality, custom options, and fast turnaround as a leading support washers company.

What Are Support Washers?

Support washers are specialised mechanical components designed to reinforce fastening points in materials prone to deformation or failure. They provide a stable surface area that distributes load more evenly across soft, brittle, or non-metallic materials.

Unlike standard washers, support washers are typically thicker, larger in diameter, and manufactured from more robust materials. They act as a structural backing to prevent pull-through, surface damage, and long-term joint failure.

Advantages of Using Support Washers

When engineered and applied correctly, support washers offer multiple mechanical and operational advantages across industries.

1. Material Protection

Support washers protect vulnerable surfaces—such as rubber, plastic, cork, or composite panels—by preventing them from being crushed, cracked, or distorted under bolt or screw pressure.

2. Improved Load Distribution

By spreading force over a wider contact area, support washers reduce the risk of material failure at fastening points. This improves long-term structural integrity.

3. Enhanced Seal Performance

In systems using soft gaskets, support washers ensure even compression, which preserves the effectiveness of the seal and reduces the chance of leaks.

4. Increased Assembly Longevity

Support washers improve the durability of bolted joints, reducing the frequency of repairs or replacements in high-load or high-vibration environments.

5. Versatility Across Applications

Their mechanical versatility makes support washers suitable for plumbing, electrical systems, automotive components, marine equipment, aerospace structures, and general industrial use.

Key Applications of Support Washers

Support washers are used across a wide range of industries, where protecting soft or fragile materials is essential to maintaining structural performance and safety.

Support washers prevent rubber seals and cork gaskets from tearing or pulling through under pressure. Engineers and technicians widely use them in plumbing systems, engine assemblies, and pipe fittings to maintain sealing integrity.

Advantages of Using Support Washers

When engineered and applied correctly, support washers offer multiple mechanical and operational advantages across industries.

1. Material Protection

Support washers protect vulnerable surfaces like rubber, plastic, cork, or composite panels from being crushed, cracked, or distorted under bolt or screw pressure.

2. Improved Load Distribution

By spreading force over a wider contact area, support washers reduce the risk of material failure at fastening points. This improves long-term structural integrity.

3. Enhanced Seal Performance

In systems using soft gaskets, support washers ensure even compression, which preserves the effectiveness of the seal and reduces the chance of leaks.

4. Increased Assembly Longevity

Support washers improve the durability of bolted joints, reducing the frequency of repairs or replacements in high-load or high-vibration environments.

5. Versatility Across Applications

Their mechanical versatility makes support washers suitable for plumbing, electrical systems, automotive components, marine equipment, aerospace structures, and general industrial use.

Industry-Specific Material Options

Stephens Gaskets manufactures support washers in a broad range of materials. Each is selected based on load requirements, environmental conditions, and application standards.

1. Automotive and Heavy-Duty Machinery

- Hardened steel for strength under high mechanical loads.

- Stainless steel for long-term resistance to corrosion.

2. Plumbing and HVAC

- Brass for corrosion resistance and water compatibility.

- Stainless steel for wet or chemically reactive environments.

3. Electrical and Electronics

- Brass or copper for conductivity when required.

- Nylon or insulating composites combined with metal for protection and mechanical support.

4. Aerospace and Defence

- Titanium for lightweight strength and corrosion resistance.

- High-grade stainless steel for fatigue resistance in demanding applications.

5. Industrial Equipment

- Zinc-plated or black-oxide carbon steel for affordable durability.

- Hardened steel for high-load, high-stress environments.

6. Marine and Offshore Use

- 316 stainless steel for long-term saltwater resistance.

- Duplex stainless steel for extreme strength and corrosion resistance.

Issues Support Washers Solve

Choosing the right washer prevents a wide range of mechanical issues that can cause delays, damage, or system failure.

Without Support Washers:

- Soft materials such as rubber or plastic become damaged or pulled through fasteners.

- Gaskets can be displaced, resulting in seal failure and leaks.

- Bolted joints may loosen over time, requiring frequent maintenance.

- Cracking in brittle components can cause short circuits or breakdowns.

- Vibration can weaken joints and reduce performance.

- Corrosion from material mismatch leads to early failure.

With Support Washers:

- Fastening pressure is distributed evenly and safely.

- Gasket integrity is maintained over time.

- Joints remain tight and stable under vibration.

- Material-specific choices eliminate galvanic corrosion.

- Systems run reliably with reduced maintenance needs.

FAQs

What is a support washer and why is it needed?

How do support washers differ from standard washers?

Where are support washers typically used?

What material should I choose for my application?

Can support washers be used in vibration-prone environments?

Will support washers fit standard fasteners?

Why Choose Stephens Gaskets?

As a long-standing support washers supplier, we have built a reputation for delivering high-quality products, expert service, and value. With decades of experience, a wide-ranging inventory, and a technical team ready to assist, Stephens Gaskets is the ideal partner for your fastening needs.

We are trusted by engineers, manufacturers, and OEMs across the UK for reliable components and tailored solutions. Whether you are securing delicate electronics or high-load machinery, we can help you protect your investment.

Our commitment to quality is backed by:

- ISO-certified processes.

- Rigorous quality checks.

- In-house UK manufacturing.

- Full material traceability.

Order or Enquire Today

Whether you need 50 units or 5,000, we can support your requirements.