Electrical Motor Laminations

Electrical Motor Laminations

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Are Electrical Motor Laminations?

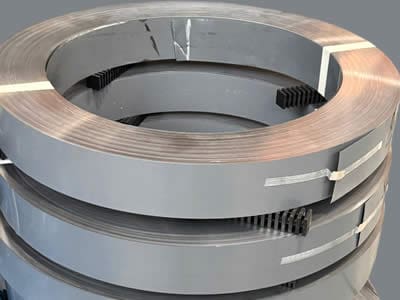

Electrical motor laminations are thin sheets of electrical steel, also known as silicon steel, stacked to form a motor’s magnetic core. They reduce eddy current losses – a key cause of wasted energy and heat in electric motors.

Why Choose Stephens Gaskets?

- UK Manufacturing Expertise: Over 70 years producing precision-engineered laminations.

- Low-Loss Laminations: Manufactured from high-grade NOES and CRNGO steels.

- Custom Design Capability: Bespoke stator and rotor laminations for any application.

- Prototype to Production: Laser-cut prototypes, high-speed press for volume.

- Certified Materials: Full traceability and insulation coatings that meet IEC standards.

- Fast Turnaround: Reliable UK and global delivery with consistent quality control.

Key Benefits

1. Reduced Energy Losses

Laminations block eddy currents for maximum efficiency.

2. Cooler Operation

Less heat = longer motor lifespan and reduced cooling needs.

3. Superior Magnetic Properties

High permeability steels ensure efficient flux flow.

4. High-Frequency Compatibility

Thin laminations improve performance in inverter-driven motors.

5. Cost Savings

Lower power use and maintenance overheads.

6. Sustainability

Energy efficiency supports green initiatives in EVs and renewables.

Applications of Electrical Motor Laminations

Our laminations are used in virtually every electric power system, including:

Materials & Manufacturing

We produce laminations using advanced magnetic alloys to suit each industry:

| Material | Typical Use | Benefit |

|---|---|---|

| Non-Oriented Electrical Steel (NOES) | Motors, Generators | Balanced magnetic properties for rotating machines. |

| High-Silicon Steel (3.5%+ Si) | EVs, Aerospace | Low eddy currents and high resistivity. |

| Nickel-Iron Alloys (Permalloy) | Aerospace, Medical | High permeability, low losses. |

| Cobalt-Iron Alloys (Hiperco) | Defence, Aerospace | High saturation flux density & temperature tolerance. |

| Amorphous Alloys | High-Frequency Motors | Ultra-low losses and compact design. |

Industry Pain Points – and How We Solve Them

| Buyer Challenge | Our Solution |

|---|---|

| Energy inefficiency & overheating | Precision laminations reduce eddy current losses and heat buildup. |

| Supply chain delays | UK-based production ensures fast lead times and reliability. |

| Noise & vibration issues | Burr-free edges and low-magnetostriction steels minimise hum. |

| Material costs & waste | Optimised cutting and nesting reduce scrap rates. |

| Compliance pressures (IE4/IE5, EcoDesign) | Premium electrical steels ensure full regulatory compliance. |