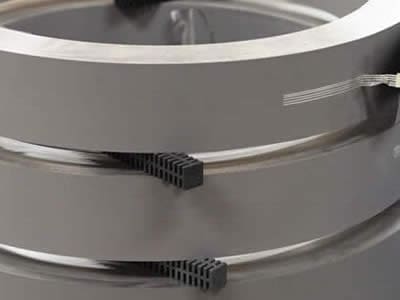

Electrical Steel Sheets

Electrical Steel Sheets

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Is an Electrical Steel Sheet?

An Electrical Steel Sheet (also known as silicon steel, lamination steel, or transformer steel) is a specially engineered alloy designed to offer high magnetic permeability and low energy loss when exposed to alternating magnetic fields.

Composition & Structure

- Iron with 2-6% silicon to increase resistivity and lower eddy current losses.

- Grain-oriented (GO) steels: aligned crystal structure for minimal core loss – ideal for transformers.

- Non-grain-oriented (NGO) steels: random grain orientation – ideal for motors and generators.

Benefits of Electrical Steel Sheets

| Benefit | Description |

|---|---|

| High Energy Efficiency | Low hysteresis and eddy current losses reduce wasted energy. |

| Improved Magnetic Performance | High magnetic permeability allows smooth magnetic flux transfer. |

| Sustainability | Increases energy efficiency, lowers emissions, and supports net-zero goals. |

| Compact, Lightweight Designs | Enables smaller, more efficient machines – critical for EVs and aerospace. |

| Extended Equipment Lifespan | Reduced heat generation lowers stress and maintenance needs. |

| Economic Advantage | Lower operational costs and faster ROI through energy savings. |

Applications of Electrical Steel Sheets

Electrical steel sheets are critical anywhere electricity and magnetism interact:

Materials & Manufacturing

Stephens Gaskets produces electrical steel sheets using low-carbon iron alloys with carefully controlled additions for magnetic performance:

| Material Element | Purpose |

|---|---|

| Silicon (2-6.5%) | Increases resistivity, reducing eddy current losses |

| Aluminium (Al) | Refines magnetic domains and improves stability |

| Manganese (Mn) | Boosts strength and deoxidizes steel |

| Phosphorus (P) | Improves resistivity but used in trace amounts to avoid brittleness. |

Industry Pain Points (and How We Solve Them)

| Industry Challenge | Stephens Gaskets Solution |

|---|---|

| High energy losses | Silicon-alloyed steel reduces hysteresis and eddy currents |

| Overheating & noise | Precision rolling and coating improve magnetic smoothness. |

| Heavy or bulky equipment | Efficient flux conduction allows compact, lightweight designs. |

| Short component lifespan | Lower core losses reduce thermal stress and improve reliability. |

| Sustainability & compliance | Materials meet EU EcoDesign and global energy standards. |