In precision engineering, accuracy defines performance. The tighter the tolerance, the more reliable the outcome.

When machinery operates under extreme stress, speed, or heat, even the smallest misalignment can compromise efficiency or cause premature wear.

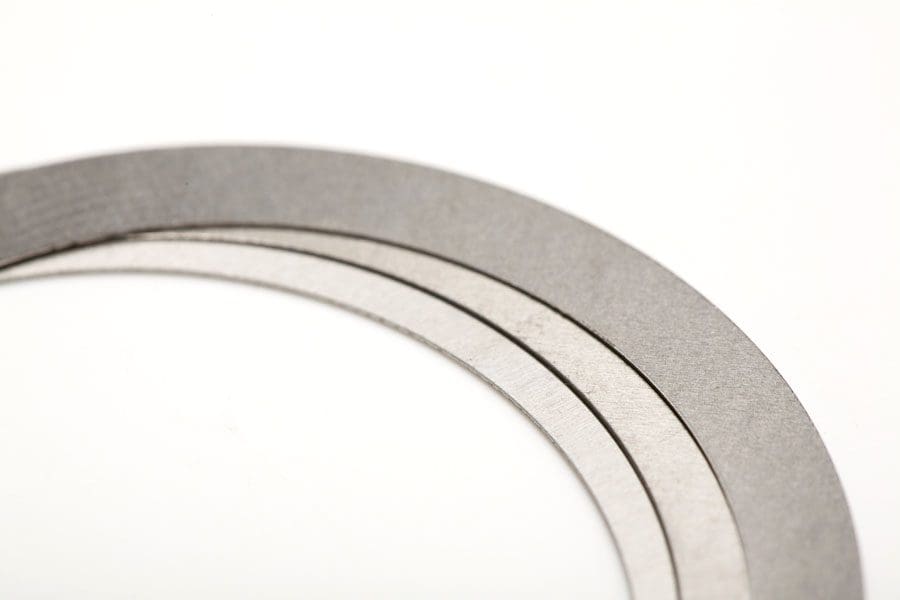

That’s where high-precision shim washers come in.

Stephens Gaskets has been manufacturing precision-engineered shims and washers for over 70 years.

Our components support engineers across sectors like aerospace, automotive, power generation, defence, and heavy industry, where reliability can never be left to chance.

This article explores what makes precision shim washers vital, how they’re made, and why accuracy at the micron level is essential for world-class engineering projects.

What Are High-Precision Shim Washers?

A high-precision shim washer is a finely machined, ultra-flat component used to create exact spacing, alignment, or load distribution between parts in an assembly.

Unlike standard washers, which are made in bulk to general sizes, precision washers are manufactured to exact specifications — often within tolerances as fine as ±0.005mm.

They play a crucial role in:

- Adjusting alignment during assembly or maintenance

- Reducing vibration and friction between moving parts

- Preventing uneven loading or binding

- Improving energy efficiency and lifespan of components

From gas turbines and transmission systems to robotic assemblies, these washers act as the silent heroes of engineering — ensuring everything operates as it should.

Why Precision Matters

Precision determines performance. A 0.05mm misalignment in an engine, gearbox, or turbine can create excess vibration, heat, and friction, leading to accelerated wear or even catastrophic failure.

High-precision shim washers eliminate those risks. By introducing exact spacing between mating parts, they help maintain consistent mechanical performance under demanding conditions.

Stephens Gaskets achieves this through:

- CNC machining and laser cutting for unrivalled accuracy

- Controlled manufacturing environments for dimensional stability

- Comprehensive inspection using coordinate measuring machines (CMM)

Every washer we produce undergoes stringent checks to ensure it meets the client’s exact drawing or CAD model.

How High-Precision Shim Washers Are Manufactured

Producing a washer that meets micron-level accuracy requires both technology and expertise.

At Stephens Gaskets, each production run follows a rigorous, ISO-certified process that includes:

1. Material Selection:

The process starts with selecting the correct material — typically stainless steel, brass, copper, or aluminium — based on the operational environment, load, and temperature range.

2. Cutting & Forming:

We use laser cutting for ultra-fine accuracy and press tooling for higher volume production.

For complex geometries, CNC milling and wire EDM are used to achieve intricate profiles without burrs or deformation.

3. Deburring & Surface Finishing:

After cutting, components are cleaned, deburred, and surface-finished to achieve smooth, consistent edges and optimum performance in tight-fitting assemblies.

4. Inspection & Quality Assurance:

Every part is checked for dimensional accuracy, flatness, and finish. Our QA process includes laser scanning and manual inspection against CAD drawings to ensure compliance with exact specifications.

5. Certification & Packaging:

Each batch is supplied with full material traceability and inspection certificates for complete engineering accountability.

This process ensures 100% repeatable precision for every part we produce — from one-off prototypes to full-scale production orders.

Applications Across Engineering Sectors

High-precision shim washers are used wherever exact spacing or alignment is required between mechanical components.

Stephens Gaskets supplies precision washers for industries including:

- Aerospace: Engine mounts, turbine blades, control systems, and landing assemblies where weight and balance are critical.

- Automotive: Gearbox assemblies, engine mounts, and suspension systems that require vibration-free operation.

- Power Generation: Gas and steam turbines, alternators, and electrical systems where small inaccuracies can cause significant inefficiency.

- Manufacturing & Robotics: Automation systems, jigs, and fixtures where repeatability defines success.

- Defence & Marine: Equipment exposed to vibration, heat, and pressure that must maintain perfect alignment under load.

- Medical & Instrumentation: Precision mechanisms that rely on ultra-flat, contamination-free washers.

Wherever precision matters, Stephens Gaskets delivers.

The Benefits of High-Precision Shim Washers

Enhanced Performance

Tight-tolerance washers improve overall machine efficiency by maintaining ideal spacing and alignment between components.

Reduced Wear & Downtime

Precision spacing reduces friction, vibration, and contact stress, extending part lifespan and reducing maintenance intervals.

Improved Energy Efficiency

When assemblies operate smoothly, energy loss through friction or vibration is reduced — saving time, cost, and energy.

Custom Engineering

We tailor every washer to your exact requirements, including material, coating, and surface finish.

Complete Quality Assurance

All washers are produced under ISO 9001:2015 standards with batch traceability and inspection certification available.

Why Engineers Choose Stephens Gaskets

With more than seven decades of experience, Stephens Gaskets is one of the UK’s most respected names in precision shim manufacturing.

Our reputation is built on:

- Consistency: Every part we deliver meets the same high standards, no matter the volume.

- Accuracy: Achieving tolerances within microns.

- Speed: Rapid prototyping and short lead times for urgent projects.

- Expertise: Engineers with decades of practical experience in shim design and production.

- Innovation: Continual investment in new materials, machines, and inspection technology.

We don’t just manufacture parts — we manufacture confidence.

Choosing the Right Material for Precision Washers

Each material performs differently under stress, temperature, and chemical exposure.

Stephens Gaskets advises on the best option for your project based on load, environment, and budget.

- Stainless Steel: Resistant to corrosion and ideal for demanding environments like aerospace and food manufacturing.

- Brass: Perfect for electrical conductivity and anti-corrosive applications such as marine or electrical assemblies.

- Copper: Offers superior thermal and electrical properties for use in motors, transformers, and energy systems.

- Aluminium: Lightweight and cost-effective for automotive and aerospace projects.

- Plastics (PTFE, Nylon): Non-metallic, corrosion-resistant, and excellent for insulation and chemical applications.

Selecting the right material ensures long-term reliability and performance, especially under thermal or dynamic stress.

Quality Control and Testing

Stephens Gaskets operates under strict quality management procedures.

Each precision washer is measured, inspected, and documented for compliance.

Our inspection process includes:

- Laser-based measurement for dimensional verification

- CMM inspection for 3D geometry checks

- Visual and surface analysis for uniformity

- Documentation for full traceability

- Quality is built into every stage of our production cycle.

Common Buyer Challenges (and How We Solve Them)

Challenge 1: Inconsistent washer tolerances from overseas suppliers.

Solution: UK-based manufacturing ensures every batch meets certified tolerances, removing uncertainty.

Challenge 2: Long lead times for prototypes or small runs.

Solution: Our rapid prototyping service can deliver parts within days.

Challenge 3: Material compatibility or fatigue issues.

Solution: We provide expert advice on suitable materials and coatings.

Challenge 4: Documentation and traceability gaps.

Solution: Every order includes certification, material test reports, and batch traceability.

Challenge 5: Limited stock or repeat order variability.

Solution: Our digital production tracking ensures consistency across repeat orders — every time.

Frequently Asked Questions

Q1: What tolerance levels can Stephens Gaskets achieve?

A: Depending on material and thickness, we can produce washers with tolerances as fine as ±0.005mm.

Q2: Can you manufacture custom shapes?

A: Yes — we can produce any shape or profile from customer drawings or CAD models using laser or CNC cutting.

Q3: What materials are available for precision washers?

A: Stainless steel, brass, copper, aluminium, PTFE, and other metals or polymers.

Q4: Do you offer certification for aerospace or defence applications?

A: Yes — we provide full traceability and documentation to meet ISO and AS9100 quality standards.

Q5: How fast can you deliver precision shims or washers?

A: Lead times vary by quantity and material, but prototype orders can be fulfilled within days.

For engineering-grade accuracy, partner with Stephens Gaskets — the UK’s precision shim manufacturing specialist.

📞 Call 0121 544 5808

✉️ sales@stephensgaskets.co.uk

🌐 Visit www.stephensgaskets.co.uk