As sustainability becomes a core priority in global manufacturing, companies are under pressure to cut waste, lower emissions, and reduce energy use. At Stephens Gaskets, we’ve integrated technologies that support both performance and planet. One standout method is laser cutting as a sustainable manufacturing method.

This blog explores the environmental benefits of laser cutting, how it supports eco-friendly manufacturing, and why more industries are choosing Stephens Gaskets for sustainable laser cutting services that align with long-term environmental goals.

Why Laser Cutting is Environmentally Superior

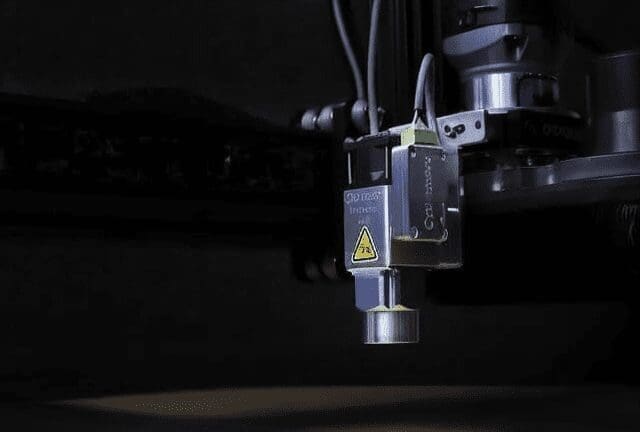

Laser cutting offers clear environmental advantages over traditional cutting techniques. By combining high precision with reduced energy consumption, it allows for more responsible production at scale.

Key Benefits:

- Reduced Material Waste

Precision cutting ensures minimal offcuts. Materials like brass, stainless steel, and aluminium are used more efficiently, cutting back on costs and waste. - Lower Energy Consumption

Our modern CNC laser machines are engineered for energy efficiency. Faster job cycles mean less time and energy per component. - Cleaner Operation

Laser cutting is contactless. No blades, no debris, no mess. That results in safer, cleaner workspaces with less environmental contamination.

Stephens Gaskets’ Sustainable Manufacturing Commitment

With over 70 years of experience, Stephens Gaskets continues to lead in responsible UK manufacturing. Our investment in sustainable laser cutting is part of a wider strategy to support greener operations without compromising on quality.

How We Do It:

- Optimised Material Nesting

We use advanced nesting software to plan layouts that make the most of every sheet. Less waste, more efficiency. - Low-Energy Machines

Our CNC laser systems use modern, energy-conscious design to reduce power usage. - Sustainable Operations

From waste management to lighting, our facility operates under eco-efficient principles.

We don’t just follow environmental guidelines — we build sustainability into every stage of our process.

Industry Use Cases for Sustainable Laser Cutting

More sectors are embracing eco-friendly manufacturing. Here’s how laser cutting supports sustainability across industries:

Electronics

Tight tolerances mean lower waste. Laser cutting allows for ultra-precise parts using the least amount of material possible.

Automotive

Car makers are adopting greener practices. Laser cutting supports lightweight part production with minimal offcut and lower energy demand.

Packaging

Custom packaging solutions benefit from laser cutting’s precision. Less filler, fewer resources, and better use of recycled materials.

FAQs

Is laser cutting more sustainable than mechanical cutting?

Yes. Laser cutting produces less waste, uses less energy, and eliminates the need for physical tooling.

Can laser cutting help meet my environmental goals?

Definitely. With reduced emissions and waste, it supports environmental standards and CSR targets.

What materials can be cut sustainably?

We work with stainless steel, copper, aluminium, and more — all cut with high efficiency and low environmental impact.

Does Stephens Gaskets support custom sustainable projects?

Yes. We partner with clients to deliver precise, eco-friendly solutions across a range of industries.

Conclusion: Partnering for a Greener Future

Laser cutting as a sustainable manufacturing method offers more than technical precision — it offers a way forward for manufacturers aiming to reduce environmental impact. At Stephens Gaskets, our advanced systems and expert team deliver on both sustainability and performance.

Join us in building a cleaner, smarter future for manufacturing — without compromising on quality or reliability.

Contact Stephens Gaskets

Phone: +44 (0)121 544 5808

Email: sales@stephensgaskets.co.uk

Work with Stephens Gaskets — where precision meets responsibility.