Laser Precision for Automotive Innovation

Laser Precision for Automotive Innovation

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Is Laser Cutting for Automotive?

Laser cutting for automotive applications involves using high-powered fibre or CO₂ lasers to cut metal or plastic components to exact tolerances. This technique enables quick turnaround, complex geometries, and clean edges without the need for secondary finishing.

Why Use Laser Cutting in the Automotive Sector?

- Precision at Scale:

Tight tolerances and repeatability are crucial. Our systems can produce thousands of identical parts or single prototypes with equal accuracy. - Speed to Market:

Laser cutting reduces lead times. It’s ideal for development stages or production when timing is critical. - Material Versatility:

We work with aluminium, stainless steel, mild steel, copper, and technical plastics. Each is suitable for different automotive systems, including engine mounts, exhaust assemblies, and interior fixtures. - Cost-Efficiency:

Especially for small batches or highly detailed components, laser cutting minimises tooling costs and waste.

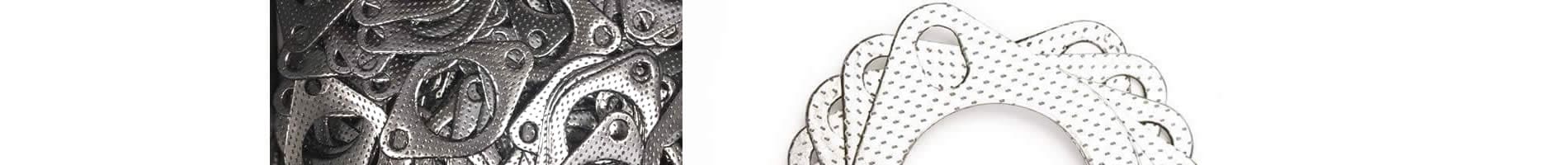

Automotive Components We Laser Cut

- Gaskets and shims.

- Heat shields.

- Brackets and flanges.

- Sensor housings.

- Custom washers.

- Battery casing parts (EV sector).

- Trim components.

If it needs precision and performance, we can cut it.

Materials Used for Automotive Laser Parts

- Stainless Steel: for corrosion resistance and strength.

- Aluminium: lightweight and conductive, ideal for EVs.

- Mild Steel: cost-effective structural use.

- Copper & Brass: for electrical conductivity.

- Plastics: for non-conductive or lightweight needs.

All materials are traceable and meet automotive-grade standards.

Quality Assurance & Certifications

We understand the automotive industry demands robust quality systems:

- ISO 9001:2015 certified.

- Full material certification on request.

- Inspection reports available.

- Repeatability testing for batch orders.

- Cleanroom-compatible packaging for sensitive components.

Case Studies: Our Work in Automotive

- Electric Vehicle Manufacturer (UK):

Stephens Gaskets delivered 10,000 precision-cut copper battery shims within 7 working days. Each part required electrical conductivity testing and 0.1mm tolerance. - Tier-1 Engine Supplier:

Produced a series of stainless steel mounting brackets with laser-etched ID numbers and heat resistance for turbo applications. - Classic Car Restoration Firm:

Crafted custom laser-cut panels from aluminium with a brushed finish to match period-correct interiors.

Why Stephens Gaskets?

- Over 70 years of UK manufacturing expertise.

- Rapid quote and delivery times.

- Low-to-high volume capacity.

- Custom design support.

- Experienced in automotive compliance.

We are more than a laser cutting service provider. We are your engineering partner.