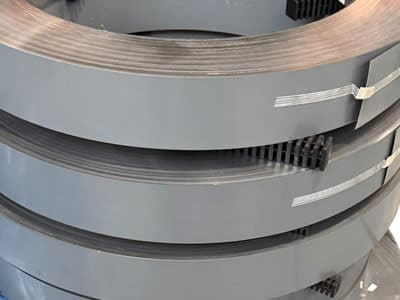

Electrical Steel Foil

Electrical Steel Foil

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Our ultra-thin magnetic foils – ranging from 20 to 100 μm – deliver exceptional energy efficiency, reduced core losses, and superior performance in compact devices such as EV chargers, transformers, and aerospace power systems.

What Is Electrical Steel Foil?

Electrical steel foil is an advanced, ultra-thin form of electrical (silicon) steel – typically below 0.1 mm thick.

Why Foil Over Traditional Laminations?

- 80 – 90% lower eddy current losses at high switching speeds.

- Enables miniaturisation for compact systems.

- Lightweight and flexible for advanced core designs.

- Improved thermal control in high-density power electronics

Benefits of Electrical Steel Foil

| Benefit | Description |

|---|---|

| Energy Efficiency | Reduces eddy current losses, improving overall efficiency. |

| Compact Design | Enables smaller, lighter magnetic components – vital for EVs and aerospace. |

| Thermal Stability | Dissipates heat effectively, extending component lifespan. |

| High-Frequency Compatibility | Perfect for inverters, converters, and power electronics. |

| Design Flexibility | Can be wound, layered, or stacked into innovative core geometries. |

| Sustainability | Supports lighter, more efficient electrification technologies. |

Applications

Electrical steel foil is used where conventional laminations are too thick or lossy for performance demands:

Industry-Specific Materials

Stephens Gaskets supplies multiple grades of electrical steel foil depending on your application and frequency range:

| Material | Typical Use | Key Advantage |

|---|---|---|

| Silicon Steel Foil (NOES/GOES) | General transformers, motors | Excellent magnetic performance and availability |

| High-Silicon Electrical Steel (6.5% Si) | EV inverters, aerospace power | Ultra-low losses at high frequencies |

| Amorphous Metal Foil | Transformers, renewables | Metallic glass structure = 70% lower core losses |

| Nanocrystalline Foil | Aerospace, medical, high-frequency | High permeability, low loss, compact form factor. |

| Hybrid Insulated Foils | EV and telecoms | Heat-resistant and corrosion-protected coatings. |

Pain Points (and How We Solve Them)

| Industry Challenge | Stephens Gaskets Solution |

|---|---|

| High Cost of Exotic Alloys | Lean manufacturing and in-house tooling reduce costs. |

| Brittle High-Silicon Steels | Precision handling and custom annealing minimise breakage. |

| Complex Foil Winding | CNC-controlled winding and lamination lines ensure consistency. |

| Thermal Stability at High Load | Special coatings improve heat resistance. |

| Limited Global Supply | UK-based production ensures fast, reliable delivery. |