CNC Gasket Cutting Service

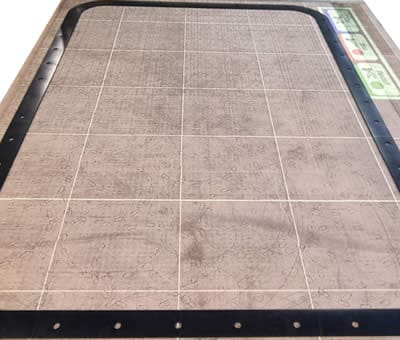

CNC Gasket Cutting Service by Experts in Precision Sealing

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Our CNC cutting capabilities let us respond quickly to bespoke requirements, changes in design, or urgent orders – without compromising quality.

Why Choose Stephens Gaskets?

As a leading CNC Gasket Cutting Company,

We provide:

- No tooling or die charges.

- Same – day or next-day turnaround on many jobs.

- CAD design and reverse engineering support.

- Access to industry-grade materials.

- Expert advice from our in-house team.

What Is CNC Gasket Cutting?

CNC (Computer Numerical Control) gasket cutting is a process where a digital design file is used to guide a cutting machine. This produces gaskets to exact specifications using materials like rubber, graphite, PTFE, cork, or metal composites.

Key Advantages:

- No need for custom dies or manual cutting.

- Repeatable results for every batch.

- Compatible with complex or irregular shapes.

- Minimal material waste through nesting software.

Benefits of CNC Gasket Cutting

Choosing a CNC Gasket Cutting Supplier like Stephens Gaskets offers:

1. High Precision

Tolerances as tight as ±0.1mm, with uniformity across all units.

2. Fast Turnaround

No tooling delays – ideal for rapid prototyping or emergencies.

3. Cost Savings

No die costs, minimal waste, and low minimum order quantities.

4. Total Flexibility

Adapt designs quickly and easily between runs.

5. Seamless Reordering

Digital file management ensures repeat jobs are consistent.

Industries We Serve

Stephens Gaskets supports a wide range of industries with CNC-cut sealing solutions:

- Cylinder heads.

- Exhaust manifolds.

- Transmission and gearbox seals.

- Lightweight custom gaskets.

- Engine and hydraulic system seals.

- Avionics protection pads.

- Pumps, valves, compressors.

- Flange and pipework sealing.

- Machine housing panels.

- PTFE seals for chemical resistance.

- FDA-approved materials for hygiene.

- High-purity applications.

- Saltwater-resistant gaskets.

- Engine bay and deck equipment seals.

- EMI/RFI shielding.

- Dust and moisture gaskets for enclosures.

CNC-Compatible Gasket Materials

Our CNC Gasket Cutting Service accommodates a wide range of materials, including:

| Material Type | Benefits | Applications |

|---|---|---|

| Nitrile Rubber | Oil-resistant, durable | Fuel systems, compressors |

| EPDM | Steam, water, and UV resistant | Pumps, outdoor enclosures |

| Neoprene | Flexible, chemically stable | HVAC, industrial panels |

| Silicone | High-temp tolerant, FDA compliant | Food processing, pharma |

| PTFE (Teflon®) | Chemical and heat resistant | Chemical plants, cleanrooms |

| Graphite | High-temp and pressure resistant | Flanges, heat exchangers |

| Cork-Rubber | Compressible, vibration-resistant | Compressors, gearboxes |

| CAF (Compressed Fibre) | Resistant to water, steam, oils | Marine, steam systems |

| Non-Asbestos Fibre | General industrial use | Pipe flanges, valve sealing |

| Metallic Inserts | Used for reinforced or profiled gaskets | Exhausts, engine mounts |

Addressing Common Problems

Unclear Specs?

We accept drawings, CAD files, or samples – and help convert them into production-ready files.

Tight Tolerances Needed?

Our QA process includes digital measuring and dimensional checks.

Small Batches or One-Offs?

We specialise in low-volume orders – perfect for legacy parts or R&D.

Complex Materials?

We maintain stock of various industrial-grade gasket sheets, and advise on the best fit.

Our Team can assist with material choice, design edits, and urgent quotes.

Real Use Case: Vintage Car Gasket

A client restoring a 1960s sports car needed a rare gasket no longer manufactured. They sent us a photo and a sketch. Within 24 hours, we provided a CAD design, cut a test gasket in nitrile rubber, and shipped it next day. The seal was a perfect fit.

About Stephens Gaskets

Stephens Gaskets is a UK-based CNC Gasket Cutting Company with decades of experience in the precision sealing industry. From OEM manufacturers to independent engineers, we’ve helped thousands of clients get the right gasket – on time, every time.

All production is handled in-house, ensuring consistent quality, full traceability, and expert technical support throughout.

FAQs

What file formats do you accept?

Is there a minimum order?

What's your typical lead time?

Do you offer trade pricing?

Can I request a prototype or sample?

Work With a Trusted CNC Gasket Cutting Supplier

Email us your drawing, idea, or sketch today – we’ll take care of the rest.