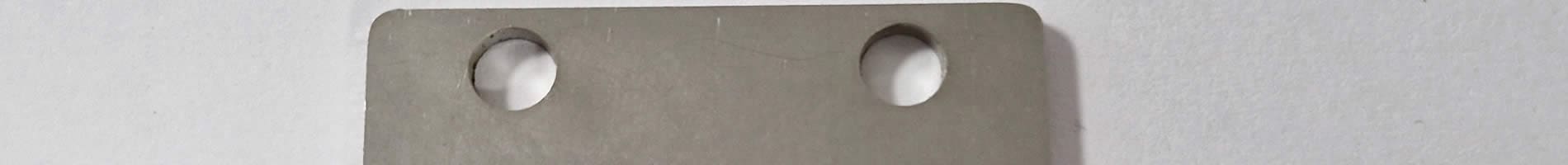

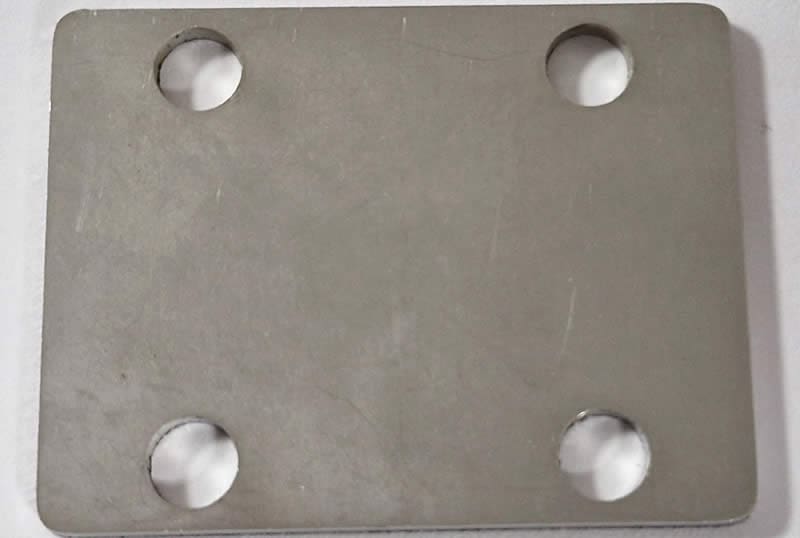

Shim Plates

Shim Plates for High-Precision Alignment, Leveling & Spacingbr />Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Are Shim Plates?

Shim plates are thin, flat components used to adjust spacing, alignment, or elevation between parts in mechanical systems.

Essential in any industry that requires precision assembly or machinery calibration, shim plates allow engineers to fine-tune tolerances without altering core components.

Key Benefits of Shim Plates

1. Precision Alignment

These plates ensure tight tolerances by adjusting the position of mechanical parts with sub-millimetre accuracy. Ideal for machinery, structural installations, and sensitive assemblies.

2. Cost-Effective Adjustment

Rather than modifying parts or casting new components, shim plates allow fast, economical realignment – saving time, money, and resources during both installation and maintenance.

3. Fast Installation & Removal

Easily slotted into position or removed during servicing. Reduces downtime and makes servicing or calibration quick and repeatable.

4. Versatility Across Applications

Used in virtually every engineering sector – from automotive and aerospace to construction, tooling, and R&D.

5. Customisable to Your Needs

We produce shim plates in a wide range of shapes (rectangular, circular, slotted, tabbed) and materials. Laser cutting, CNC machining, and laminated peelable options are available.

6. Protects Against Wear

Acts as a buffer between components, helping reduce wear, absorb vibration, and improve mechanical longevity.

Common Applications of Shim Plates

Materials for Shim Plate Manufacturing

We manufacture shim plates in a variety of industry-grade materials to suit different environments:

| Material | Best For | Key Properties |

|---|---|---|

| Stainless Steel | Harsh environments, heavy machinery | Strong, corrosion-resistant (304, 316, 321) |

| Mild Steel | Structural setups, general fabrication | Durable and cost-effective |

| Brass | Electrical components, decorative applications | Non-magnetic, corrosion-resistant |

| Copper | Electronics, thermal management | Conductive, malleable |

| Aluminium | Aerospace, lightweight machinery | Lightweight, corrosion-resistant |

| Plastics (Nylon, PTFE, Acetal) | Electrical insulation, low-friction settings | Non-conductive, corrosion – and chemical-resistant |

| Laminated Peelable Shims | Adjustable setups, prototyping | Peelable layers for on-site thickness control |

Why Choose Stephens Gaskets?

As a leading shim plates manufacturer, we’ve supported industries across the UK and globally for over 70 years.

- Precision manufacturing for custom and standard parts.

- UK-based production and technical support.

- ISO-certified quality and traceability.

- Flexible order volumes – from one to thousands.

- Expert guidance on material, spec, and fitment.

We serve customers in aerospace, automotive, food processing, power generation, electronics, and general manufacturing.

FAQs

How do I know what thickness I need?

Can I get a custom shape?

Are your materials industry compliant?

Do you supply in bulk?

Is delivery fast?

Contact Us

We can help you specify, design, or order shim plates that meet your technical and commercial needs – quickly and reliably.