Hinge Shims

High-Precision Hinge Shims for Door Alignment and Repair

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

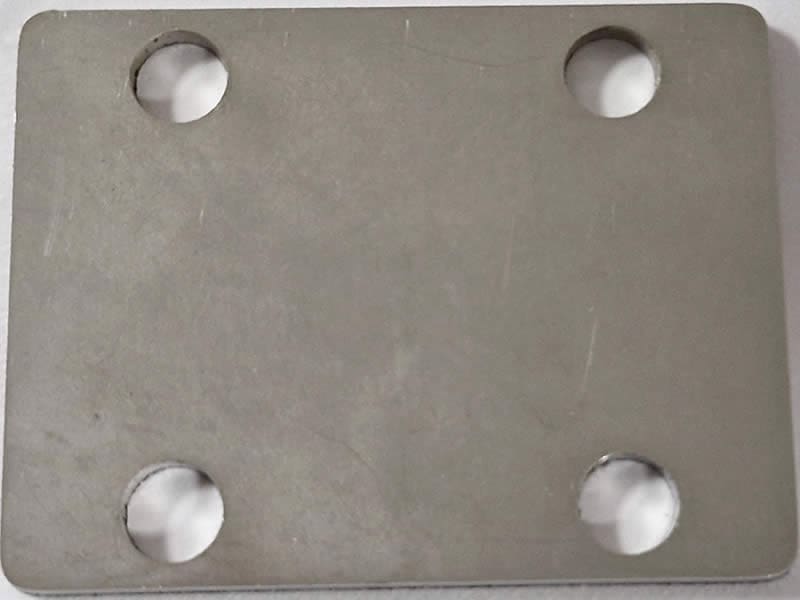

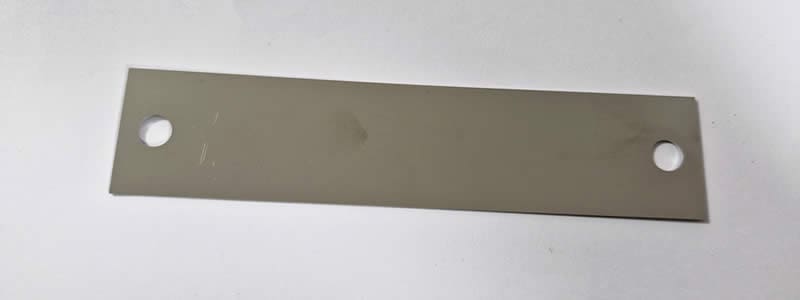

What Are Hinge Shims?

At Stephens Gaskets we manufacture hinge shims. Hinge shims are thin, flat inserts placed behind door hinges to adjust alignment and correct fitting issues. They’re used to fine-tune a door’s position without needing to rehang it, trim the frame, or make structural changes.

By adjusting the depth of the hinge on one side, hinge shims correct problems like:

- Doors that rub against the frame or floor.

- Sagging or misaligned doors.

- Uneven gaps between door and frame.

- Doors that won’t latch or seal properly.

Benefits of Using Hinge Shims

1. Fast and Easy Alignment

Rather than removing the entire door, you simply loosen the hinge screws, insert the shim, and retighten. No specialist tools required.

2. Fix Common Issues

Ideal for:

- Correcting sagging or sticking doors.

- Adjusting for uneven door frames.

- Achieving an even gap for aesthetics and performance.

- Solving latch misalignment.

3. Cost-Effective Repair

Using a shim avoids the need to replace doors, hinges, or frames. It saves time, money, and materials.

4. Versatile and Adjustable

Available in different materials and thicknesses, hinge shims allow precise control. You can stack multiple shims to achieve the exact adjustment needed.

5. Suitable for New Installs and Retrofits

Whether correcting a long-standing issue or adjusting a newly fitted door, hinge shims simplify the process and reduce installation time.

Common Applications

Hinge shims are used across domestic, commercial, and industrial settings – wherever doors require precise alignment.

- Internal doors for smoother operation.

- External doors to improve sealing and security.

- Kitchen cabinets and wardrobe doors.

- Sheds, garages, and outhouses.

- Fire-rated doors requiring regulation-compliant gaps.

- Warehouse, factory, and office doors in high-use areas.

- Hotels, schools, and hospitals where regular door maintenance is essential.

- Acoustic or thermal doors requiring airtight seals.

- Heavy steel or security doors prone to long-term sag.

- French doors or double doors needing centre-gap accuracy.

- New builds for consistent installation across multiple units.

- Retrofit scenarios with existing frames or slightly out-of-square openings.

- Joinery and custom carpentry projects where finishing is key.

Materials for Industrial and Trade Use

We offer custom hinge shims in a range of durable, industry-grade materials suited to different operating environments.

1. Stainless Steel

- Ideal for heavy-duty, fire-rated, or external doors.

- Resistant to corrosion, load deformation, and temperature extremes.

2. Mild Steel (Zinc or Galvanised Finish)

- Cost-effective and strong for general manufacturing use.

- Suitable for high-volume applications.

3. Aluminium

- Lightweight and corrosion-resistant.

- Suitable for aerospace, transportation, and light industrial use.

4. Brass

- Non-sparking and conductive – ideal for electrical environments.

- Often used in precision mechanical assemblies.

5. Engineering Plastics (Nylon, PTFE, PVC)

- Chemically resistant and non-conductive.

- Perfect for electrical enclosures and interior doors.

6. Composite Materials

- Designed for harsh or specialist conditions (e.g. high vibration, temperature, or chemical exposure)

- CNC or laser cut to high tolerances.

Addressing Common Pain Points

We understand the real-world frustrations that lead customers to seek out hinge shims. Here’s how our products solve those challenges:

“There’s no time for a full door refit”

Hinge shims can be installed in minutes, minimising downtime and labour.

“The cost of replacement is too high”

Instead of replacing hinges or trimming doors, use shims to correct the issue affordably.

“Even after adjusting, the fit is still off”

Our millimetre-precise shim options allow for exact control that screws and manual adjustments can’t achieve alone.

“Heavy doors keep sagging over time”

Metal shims reinforce hinge alignment, reducing repeat maintenance.

“Fire doors must comply with gap regulations”

Hinge shims help installers meet the strict tolerances needed for certification and compliance.

“We need consistency across multiple sites”

Our pre-cut hinge shims standardise installation across jobs, speeding up project completion.

Why Use Stephens Gaskets to provide your Hinge Shims?

- Manufactured in the UK.

- Available in trade packs or custom quantities.

- Suitable for residential, commercial, and industrial use.

- Laser-cut or CNC-formed for accuracy.

- Fast delivery and technical support available.

We support both small-scale fit-outs and large trade customers with tailored hinge shim solutions.

Contact Us

Whether you’re a contractor, facilities manager, or joinery manufacturer, our team is here to help you select the right shim type, thickness, and material for your needs.