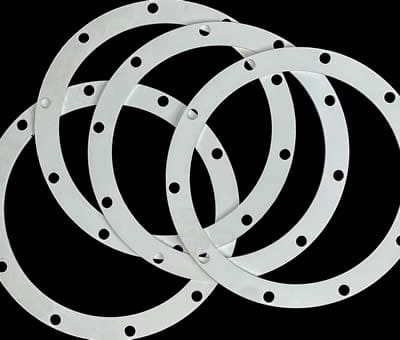

Klinger Milam PSS Gaskets

Klinger Milam PSS Gaskets for Extreme Temperature Sealing

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Is Klinger Milam PSS?

Klinger Milam PSS is a phlogopite mica-based compressed fibre gasket sheet, reinforced with stainless steel to provide strength and dimensional stability at extreme temperatures.

The name reflects the product composition:

- Milam = Klinger’s high-temperature mica-based material family.

- PSS = Phlogopite Stainless Steel.

Advantages of Klinger Milam PSS

Klinger Milam PSS is used where conventional compressed fibre, graphite, or rubber-based gaskets cannot withstand the environment. It offers key advantages in safety, performance, and reliability.

1. Extreme Heat Resistance

Performs continuously at temperatures up to 1000°C. Suitable for sealing in extreme heat environments such as turbochargers, furnaces, and high-temperature flanges.

2. Excellent Chemical Resistance

Withstands exposure to oils, fuels, acids, alkalis, and steam. This makes it ideal for aggressive media environments common in refineries and chemical plants.

3. Mechanical Strength and Blowout Resistance

The stainless steel core reinforcement gives Milam PSS strong mechanical stability, improving sealing performance under thermal cycling, pressure fluctuation, and bolt load.

4. Safe and Asbestos-Free

Offers performance equal to or exceeding legacy asbestos-based gaskets, but without health hazards. Fully compliant with modern health and safety requirements.

5. Long-Term Durability

Designed to perform under repeated thermal expansion, vibration, and mechanical load. Reduces need for frequent replacement and limits production downtime.

6. Versatility

Works in both static sealing (flanges, housings) and dynamic systems (turbochargers, high-vibration joints). Suitable for a wide range of industrial applications.

Applications of Klinger Milam PSS

Milam PSS is trusted in environments where heat, pressure, and aggressive substances make sealing difficult. It offers reliability where other gasket materials fail.

Industry-Specific Use Cases

Klinger Milam PSS is recognised across heavy industries for its durability and thermal stability. Typical sectors and equipment include:

1. Automotive and Transport

- Turbo flanges.

- Exhaust manifolds.

- EGR systems.

- Catalytic converter connections.

2. Metal and Steel Processing

- Kilns and furnaces.

- Steel ladles and converters.

- Heat treating chambers.

3. Chemical and Refinery Facilities

- Process piping and flanges.

- Reactors and scrubbers.

- Incinerators and high-temperature vessels.

4. Power Generation

- Boilers.

- Heat recovery steam generators.

- Turbine casings and housings.

5. Marine and Offshore

- Marine diesel engine exhaust.

- Scrubbers and after-treatment units.

- Turbine exhaust lines.

Limitations Addressed by Klinger Milam PSS

Milam PSS is designed to solve critical challenges found in harsh industrial environments. It offers performance where standard materials reach their limit.

- Temperature Failure of Standard Gaskets

Milam PSS operates reliably at up to 1000°C, well beyond the limits of compressed fibre, graphite, or rubber-based materials. - Blowouts and Gasket Fatigue

Stainless steel reinforcement enhances resistance to pressure and mechanical failure, especially in systems with thermal cycling. - Health and Safety Compliance

Asbestos-free and certified to meet environmental and occupational safety standards. Suitable for regulated industries. - Aggressive Chemical Exposure

Provides chemical compatibility with hydrocarbons, fuels, solvents, acids, and alkalis, extending sealing lifespan. - Reducing Unscheduled Downtime

Withstands harsh operating conditions, reducing the frequency of gasket replacement and maintenance intervals.

Why Choose Stephens Gaskets?

Stephens Gaskets is a reliable Klinger Milam PSS supplier and trusted UK source for high-performance sealing solutions.

We support customers across power generation, refining, marine, and manufacturing sectors.

We offer:

- In-house cutting and custom gasket fabrication.

- Rapid delivery across the UK and Europe.

- Technical support for application suitability and installation.

- Wide material stock, including Klinger-certified sheets.

- Flexible supply for both production and emergency maintenance.

Contact Stephens Gaskets

Need a high-temperature gasket that won’t fail under pressure?

Contact us today for Klinger Milam PSS cut gaskets or sheet material.