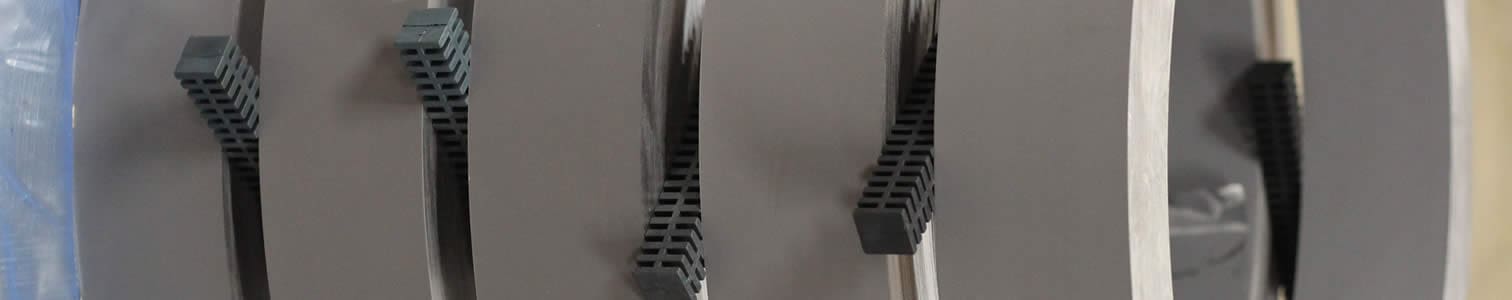

Grain Oriented Electrical Steel

Grain Oriented Electrical Steels

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

How it’s Made

For a high stacking factor and effective magnetic properties, the GOES process is always under extremely controlled conditions. As a result, this complex process of production relies on a high-silicon hot-rolled coil feedstock, before progressing onto a secondary re-crystallisation process, where some of the grains will grow to over 30mm. In addition, the magnetic properties of each coil are measured in the final vigorous testing process, where the coils are made into the correct grade needed for the customer.

The surface of grain oriented silicon steel is a glass-like film, and this provides the electrical insulation needed between wound core laps or transformer laminations. With this in mind, it differs to stainless steel in that grain oriented steel is actually sold on the basis of its magnetic properties, as well as its electrical properties. For this reason, these types of steel are also popular for manufacture reactors, as well as transformers of all sizes, including distribution transformers.

Contact Us today for more information on our competitive GOES prices, as well as the other parts we manufacturer, like shim washers.

How it’s Made

For a high stacking factor and effective magnetic properties, the GOES process is always under extremely controlled conditions. As a result, this complex process of production relies on a high-silicon hot-rolled coil feedstock, before progressing onto a secondary re-crystallisation process, where some of the grains will grow to over 30mm. In addition, the magnetic properties of each coil are measured in the final vigorous testing process, where the coils are made into the correct grade needed for the customer.

The surface of grain oriented silicon steel is a glass-like film, and this provides the electrical insulation needed between wound core laps or transformer laminations. With this in mind, it differs to stainless steel in that grain oriented steel is actually sold on the basis of its magnetic properties, as well as its electrical properties. For this reason, these types of steel are also popular for manufacture reactors, as well as transformers of all sizes, including distribution transformers.

Contact Us today for more information on our competitive GOES prices, as well as the other parts we manufacturer, like shim washers.