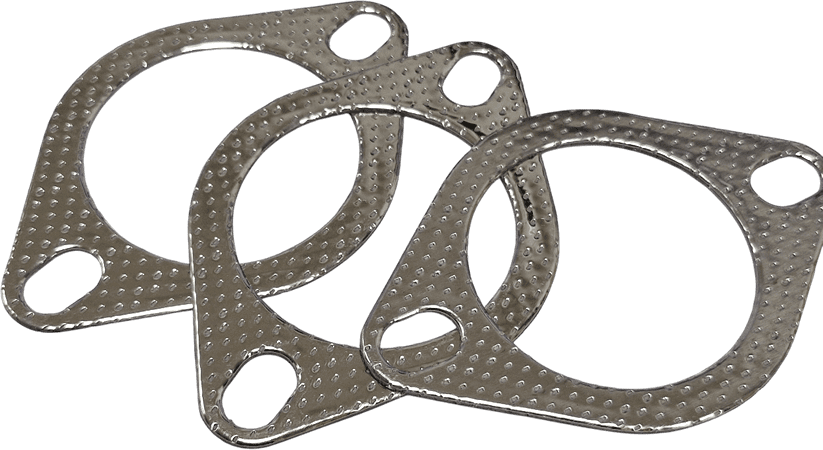

Exhaust Manifold Gaskets

Precision Exhaust Manifold Gaskets for All Engine Types

Call 0121 544 5808 Today

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

Bespoke Manufacturing

Instant Quote Service

Worldwide Delivery

Various Gauges/Thicknesses

What Are Exhaust Manifold Gaskets?

At Stephens Gaskets, we supply exhaust manifold gaskets which are essential components in any internal combustion engine.

They create a seal between the cylinder head and the exhaust manifold. This seal prevents exhaust gases from escaping and ensures efficient operation of the exhaust system.

Why Are They Important?

1. Prevent Exhaust Leaks

By sealing the joint between the engine and manifold, they stop hot gases from leaking into the engine bay. This prevents engine inefficiencies and damage to nearby parts.

2. Improve Engine Performance

A good seal ensures optimal exhaust back pressure. This improves combustion and maintains power output and fuel economy.

3. Enhance Safety and Comfort

A failed gasket can allow harmful fumes to enter the cabin or engine compartment. Proper sealing helps maintain a safe environment.

4. Support Emission Control

By directing gases through the exhaust system properly, gaskets ensure compliance with MOT and emissions standards.

5. Reduce Noise

They also reduce ticking or popping sounds often associated with leaks at the exhaust junction.

Common Applications

Exhaust manifold gaskets are used across many sectors, from personal vehicles to industrial machinery. They are engineered to meet the needs of engines operating in high-pressure and high-heat environments.

Benefits of Using High-Quality Exhaust Manifold Gaskets

1. Reliable Sealing

Gaskets ensure that no exhaust gas leaks from the manifold. This protects both the engine and its surroundings.

2. Optimised Performance

A tight seal maintains consistent exhaust flow. This keeps the engine efficient and responsive.

3. Lower Emissions

High-quality gaskets support cleaner emissions. This helps you meet environmental regulations and reduces health risks.

4. Resistance to Heat and Pressure

Materials used must withstand extreme engine conditions. We provide options suited to turbocharged or high-rev environments.

5. Noise Control

By sealing the combustion gases, gaskets also reduce ticking or loud exhaust sounds near the engine block.

6. Extended Component Life

Preventing leaks protects the cylinder head, manifold, and catalytic converter. It saves time and money in the long term.

Materials Used in Manufacturing

Choosing the right material is critical to gasket performance. We offer several options tailored to different applications and engine types.

1. Multi-Layer Steel (MLS)

Used in high-performance and heavy-duty engines. Composed of multiple layers of stainless steel, often with coatings to improve sealing and resistance.

2. Graphite

Offers excellent flexibility and thermal resistance. It compresses easily to fill gaps in older or worn components.

3. Composite Materials

Blends of metal, fibres, and rubber. Ideal for OEM or aftermarket applications that require good heat resistance and affordability.

4. Sintered Metal or Foil

Precision-cut, rigid gaskets used in performance engines. Offers long service life in demanding environments.

5. Vermiculite Coated

Withstands temperatures over 1,000°C. Used in motorsport and commercial diesel applications.

6. Copper

Highly malleable and conducts heat well. Often used in custom builds or classic vehicles.

Problems Our Gaskets Help Solve

1. Exhaust Leaks

Poor-quality or misaligned gaskets lead to gas leaks. This can harm performance, safety, and engine components.

2. Heat Damage and Blowouts

Low-grade gaskets may burn out quickly, especially in turbocharged or high-load engines.

3. Warped or Uneven Surfaces

Our gaskets can flex to fit slightly warped surfaces, preventing sealing failure.

4. Frequent Replacements

Cheap gaskets may wear out quickly. Ours are engineered to last, reducing maintenance costs.

5. Difficult-to-Source Components

We offer custom manufacturing for obsolete or uncommon gasket types.

6. Fumes in Cabins

A failed gasket can allow dangerous fumes inside the vehicle. Our precision fitment prevents this risk.

7. Fitment Issues

Misaligned gaskets cause leaks and reduce flow. Our custom and OEM-matched designs guarantee a proper fit.

Industry Use Cases

- Automotive Manufacturers

We supply both OEM and aftermarket exhaust gaskets for a range of engine types, including hybrid and diesel. - Agricultural Equipment Producers

Durable gaskets for engines that run continuously under load. - Marine and Offshore

Salt-resistant gaskets designed for harsh maritime conditions. - Generators and Stationary Power

Reliable components that reduce risk of breakdown and increase uptime. - Restoration and Custom Builds

We supply copper and composite gaskets for vintage and specialist engines.

Available Gasket Options

- Formats: Flat, beaded, embossed, MLS.

- Materials: Graphite, composite, steel, copper, vermiculite-coated.

- Quantities: One-off, short-run, or large-volume production.

- Customisation: Bespoke sizes, bolt hole patterns, and port configurations.

We work with your specifications or reverse-engineer from samples or drawings.

Why Choose Stephens Gaskets?

We are a long-standing exhaust manifold gaskets manufacturer based in the UK, known for precision, quality, and reliability.

- Trusted across automotive, industrial, and marine sectors.

- Wide material range for high-heat and high-load applications.

- No minimum order quantity.

- Technical support for material and fitment selection.

- Fast turnaround and global delivery.

We understand the importance of dependable sealing in every engine. That’s why we work closely with engineers and procurement teams to supply gaskets that meet your exact needs.

Contact Us

We offer expert advice, tailored quotations, and can support everything from prototyping to volume production.